Aluminum Gantry Crane for Clean, Anti-Corrosion & ExProof Workshops

Your Ideal Portable Aluminum Gantry Crane for Precision and Specialized Applications

The Buyer's Guide to Aluminum Gantry Cranes for Clean, Anti-Corrosion, and Explosion-Proof Workshops

The Buyer's Guide to Aluminum Gantry Cranes for Clean, Anti-Corrosion, and Explosion-Proof Workshops

Discover how to choose aluminum gantry cranes for clean, corrosion-resistant, and explosion-proof workshops. Practical tips, load guidance, and mobility features included.

Choosing the right aluminum gantry crane isn't just about picking a model off a catalog. If your workshop handles delicate materials, operates in humid or corrosive conditions, or requires strict safety measures, the wrong crane can slow down work and create extra costs. This guide is meant to help you understand what to look for in an aluminum gantry crane, from mobility and weight capacity to specialized features like corrosion resistance and explosion-proof design.

- Helps buyers identify cranes suited for portable operations

- Explains what to consider for clean and controlled environments

- Highlights features for long-term durability and safe use

Who Should Read This Guide

This guide is aimed at professionals who manage workshops or industrial facilities where precision, safety, and flexibility matter. You'll find it useful if your operation involves:

- Laboratories handling sensitive equipment or chemicals

- Food processing plants where hygiene is critical

- Pharmaceutical production requiring cleanroom compatibility

- Electronics manufacturing with delicate assemblies

- Chemical or hazardous material plants needing explosion-proof safety

Even if you run a small workshop that moves equipment around frequently, a portable aluminum gantry crane can make daily tasks much easier. Knowing what to look for before buying saves time, effort, and prevents mistakes.

Keywords in Context

Throughout this guide, we focus on helping you understand the key features of:

- Aluminum gantry cranes for lightweight, corrosion-resistant lifting

- Aluminium gantry crane options for clean and controlled environments

- Portable aluminum gantry cranes for workshops that need flexibility

- Aluminum gantry systems for reliable and safe material handling

By the end of this guide, you'll have a clear picture of which aluminum gantry crane matches your workshop's needs and which specifications matter most for safe, practical operation.

Basics of Aluminum Gantry Cranes

What Is an Aluminum Gantry Crane?

An aluminum gantry crane is a lightweight lifting device made primarily from aluminum alloys. Unlike traditional steel cranes, these cranes are designed to be easy to move, quick to set up, and flexible for different workshop layouts. Their lighter weight doesn't mean they compromise on strength; many aluminum gantries can safely lift loads from a few hundred kilograms up to several tons.

- Designed for workshops where mobility matters

- Easy to assemble and disassemble for frequent repositioning

- Ideal for operations that require space efficiency without sacrificing safety

Key Features of Aluminum Gantry Cranes

These cranes offer practical advantages that make them suitable for a variety of specialized workshops:

- Corrosion-resistant aluminum frame: Aluminum doesn't rust like steel, making it suitable for humid or chemically active environments. Smooth surfaces also make cleaning easier.

- Adjustable height and span: Many models allow you to change the height of the lifting beam or adjust the width between legs, making them versatile for different loads and spaces.

- Foldable or modular designs: Some cranes can be folded or taken apart for compact storage, which is especially useful in workshops where floor space is limited.

Common Applications

Aluminum gantry cranes are often chosen for areas where traditional overhead cranes are impractical or too heavy. They are particularly helpful in:

- Small or medium workshops with limited floor space

- Labs, cleanrooms, or food processing facilities where mobility and hygiene are important

- Situations that require lifting different types of loads in different locations within the same facility

- Temporary setups or projects where a permanent crane installation isn't feasible

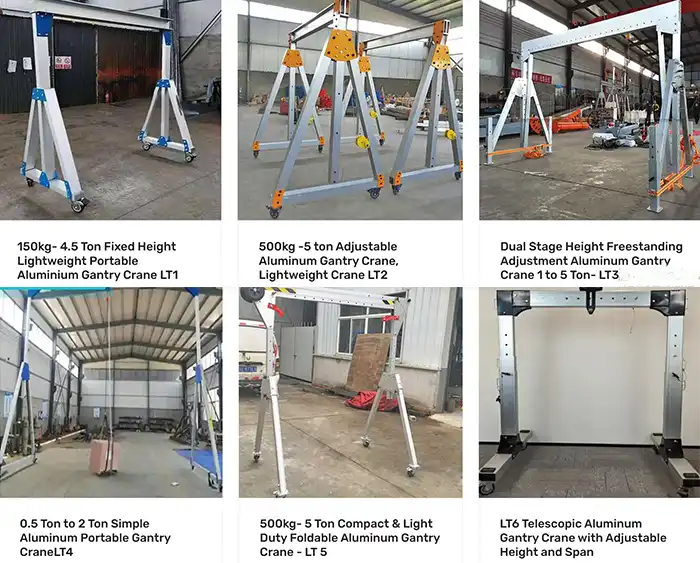

Hot-Sale Types of Aluminum Gantry Cranes

LT1 – Fixed Height Portable Aluminium Gantry Crane

- Capacity: 150 kg – 4.5 ton

- Features: Lightweight, fixed height, portable with rollers

- Best Use: General light-duty lifting with stable height requirements

LT2 – Adjustable Aluminum Gantry Crane

- Capacity: 500 kg – 5 ton

- Features: Adjustable height & span, available in portable or stationary designs

- Best Use: Flexible material handling where clearance or span varies

LT3 – Dual Stage Freestanding Adjustable Gantry Crane

- Capacity: 1 – 5 ton

- Features: Dual-stage adjustment (columns & legs), corrosion-resistant aluminum alloy

- Best Use: High-standard environments like electronics, aerospace, and university labs

LT4 – Simple Portable Aluminum Gantry Crane

- Capacity: 0.5 – 2 ton

- Features: Compact design, easy to assemble/disassemble, manual or electric castors with brakes

- Best Use: Small workshops, electronics, video production

LT5 – Foldable Aluminum Gantry Crane

- Capacity: 500 kg – 5 ton

- Features: Foldable & compact frame, light duty, easy to transport and store

- Best Use: Temporary lifting needs or workplaces with limited storage space

LT6 – Telescopic Aluminum Gantry Crane

- Capacity: Customizable within light-duty range

- Features: Telescopic height & span adjustment, portable with rollers

- Best Use: Tasks requiring maximum flexibility in lifting height and width

Workshop Features and Environment Considerations

Clean and Controlled Environments

In workshops where cleanliness is critical, the type of crane you choose can make a big difference. Aluminum gantry cranes are popular in these spaces because their smooth, corrosion-resistant surfaces are easy to clean and maintain. Portable models allow you to move the crane between stations without compromising sterile conditions.

- Smooth floors help the crane roll steadily and safely during operation.

- Low-particulate, dust-free areas reduce the risk of contamination when lifting sensitive materials.

- Proper lighting and ventilation keep both operators and equipment safe.

Cleanroom Considerations:

- Cranes with minimal joints and smooth, non-porous surfaces prevent dirt accumulation.

- Easy-to-clean designs maintain sterile conditions and reduce the risk of cross-contamination during lifting tasks.

This makes them ideal for laboratories, pharmaceutical production, electronics assembly, and food processing workshops, where maintaining a controlled environment is essential.

Corrosive or Humid Conditions

Workshops with high humidity, chemical exposure, or regular cleaning require cranes that can resist corrosion. Aluminum gantries are well-suited for these conditions. Their high-grade alloys, often combined with anodized or powder-coated finishes, provide excellent protection against rust and degradation.

- Avoiding steel components in these areas ensures longevity and reduces maintenance issues.

- Durable aluminum frames help maintain reliable performance over time, even in harsh conditions.

- Reduced maintenance and downtime mean the workshop can operate smoothly without frequent interruptions.

These corrosion-resistant gantries are practical in chemical plants, humid warehouses, and areas where cleaning agents or spills are common. Adjustable and portable designs allow flexibility while still standing up to challenging workshop conditions.

Hazardous or Explosive Environments

Some workshops handle flammable gases, powders, or chemicals, which means safety is non-negotiable. In these cases, choosing a crane with non-sparking components and fully enclosed motors and electrical systems is essential. Aluminum gantries designed for hazardous areas reduce the risk of accidental sparks that could ignite volatile substances.

- Non-sparking materials prevent accidental ignition during lifting operations.

- Enclosed electrical systems protect sensitive components from dust, moisture, and potential chemical exposure.

- Compliance with recognized explosion-proof safety standards ensures the crane is safe for use in chemical or pharmaceutical production areas.

These cranes are particularly useful in labs, powder-handling facilities, and chemical workshops where every movement must be controlled and predictable. Lightweight aluminum cranes, including jib-style configurations, allow precise positioning of loads without compromising safety.

Spatial Constraints and Mobility

Many workshops face challenges with ceiling height, narrow aisles, or irregular layouts. Portable aluminum gantry cranes are ideal in these environments because they can be adjusted, moved, or folded to fit the available space without sacrificing lifting capacity.

- Assess ceiling height, aisle width, and overall workshop layout to ensure safe crane operation.

- Make sure the floor can support the crane's weight along with its maximum load.

- Portable designs allow the crane to be repositioned quickly, making it easy to serve multiple workstations or temporary setups.

Adjustable models are particularly useful when lifting requirements vary. The ability to change height or span makes these cranes practical for workshops that handle different load sizes or need flexible workflows.

Typical Loads Handled

Understanding the loads your workshop will handle is one of the most important steps when selecting an aluminum gantry crane. Choosing a crane with the correct lifting capacity ensures safety, reduces wear on the equipment, and makes daily operations smoother. Lightweight aluminum gantries are versatile, but you still need to match the crane to the type and weight of your materials.

- Light Loads (0.25–2 tons): Ideal for small laboratory equipment, electronic assemblies, or other lightweight components. These are often lifted using smaller, portable aluminum gantries that are easy to move between stations.

- Medium Loads (2–5 tons): Suitable for machinery parts, chemical drums, or food processing bins. Cranes in this range provide a balance of portability and strength, making them practical for workshops with frequent repositioning needs.

- Heavy Loads (5–10 tons): Used for industrial molds, large machinery parts, or storage tanks. Even in heavier categories, aluminum gantries can be designed to remain manageable while still meeting lifting requirements.

It's important to include a safety margin of 20–30% above the maximum expected load to prevent overloading and extend the life of the crane. Adjustable or modular gantries can help accommodate varying load sizes without compromising stability. Whether you're using a small aluminum gantry crane for light tasks or a 5 ton aluminum gantry crane for heavier lifting, knowing your typical loads helps you pick a solution that's both practical and reliable.

Key Specifications to Evaluate

When selecting an aluminum gantry crane, it's not enough to focus solely on load capacity. The right crane also needs to fit your workshop space, be easy to move, and meet safety standards. Paying attention to these specifications ensures the crane performs reliably and reduces downtime from maintenance or operational issues.

- Load Capacity with Safety Margin: Always choose a crane rated for at least 20–30% more than your heaviest expected load. This prevents strain on the crane and ensures long-term durability.

- Adjustable Span and Height: A gantry with adjustable width and lifting height allows you to handle a variety of load sizes and reach different areas of your workshop without moving other equipment.

- Mobility: Look for lockable wheels, casters, or a fully portable design so the crane can be repositioned quickly and safely when needed.

- Quick Assembly and Disassembly: Modular or foldable gantries make setup easier and allow for compact storage when the crane is not in use.

- Safety Features: Ensure the crane includes overload protection, emergency stops, and complies with relevant safety standards for your workshop environment.

Choosing a crane that balances these features can make a big difference in daily operations. Whether you need a lightweight, portable aluminum gantry for temporary tasks or a more robust A-frame lifting gantry for heavier loads, these specifications help ensure you get a crane that is both practical and safe for your workshop.

Types and Configurations

Aluminum gantry cranes come in several types and configurations, each suited for different workshop needs. Understanding the options can help you pick the right crane for your workflow, space, and load requirements. Some are designed for heavy-duty tasks, while others focus on portability and flexibility.

- Fixed Gantry Cranes: These cranes remain stationary and provide consistent lifting at one location. They are ideal when repeated lifts are required in the same spot and when stability is a priority.

- Adjustable Gantry Cranes: With adjustable height and span, these cranes can handle a variety of load sizes and reach different areas of the workshop. They are perfect for operations where lifting requirements change frequently.

- Foldable Gantry Cranes: Designed for compact storage, foldable cranes are great for workshops with limited space or temporary lifting needs. They can be set up quickly and moved when necessary.

- Double-Stage Gantry Cranes: Built to handle heavier or specialized loads, double-stage cranes often combine sturdiness with a larger lifting height. They are useful in workshops where single-stage gantries may not be sufficient.

Whether you need a portable aluminum gantry crane for flexible use or an aluminum A-frame gantry for more stability, choosing the right type ensures both safety and efficiency. The combination of mobility, adjustability, and durability makes these cranes practical solutions for workshops of all sizes.

Cost Considerations

When it comes to aluminum gantry cranes, price is more than just a number on a quote. It reflects the materials, features, and safety standards built into the crane. Understanding the cost factors helps you make a practical investment that meets your workshop needs without overspending.

- Entry-Level Cranes: Designed for light loads and basic lifting tasks, these models are often more affordable and work well in small or low-frequency operations.

- Higher-End Cranes: More robust cranes are built for precision lifting, corrosion resistance, or explosion-proof environments. They may include adjustable spans, foldable designs, or specialized coatings for long-term durability.

- Material and Customization: The quality of aluminum, protective coatings, and any custom features significantly affect price. Choosing the right combination of materials and options ensures you get value for money.

- Long-Term Value: Investing in a well-built crane reduces maintenance costs, minimizes downtime, and improves efficiency in the workshop over time.

Whether you are looking for an aluminum gantry for sale for general lifting or a more specialized aluminium gantry for sale for controlled environments, balancing upfront cost with practical performance is key to a smart purchase.

Practical Tips for Buyers

Selecting the right aluminum gantry crane isn't just about picking a model with the correct load capacity. Small details in your workshop environment, load patterns, and mobility needs can make a huge difference in safety, efficiency, and long-term performance. Taking a few practical steps before buying ensures you get the most out of your crane.

- Conduct a Workshop Audit: Before making any purchase, measure ceiling height, aisle width, and available floor space. Check that the flooring can safely support both the crane and the heaviest loads you plan to lift. A thorough audit helps identify potential obstacles, low-clearance areas, or weight limits that could restrict crane movement.

- Document Typical Loads and Lifting Frequency: Keep track of the weight, size, and frequency of lifts in your workshop. This information ensures you select a crane with the appropriate capacity and safety margin. For example, a portable aluminum gantry that handles frequent, medium-weight lifts may need sturdier construction than one used occasionally for light loads.

- Plan for Mobility, Storage, and Repositioning: Portable aluminum gantries are designed to move, but not all models are equally easy to reposition. Consider how often the crane will need to be moved, whether it will be stored when not in use, and if foldable or adjustable designs would make daily operations smoother. Wheels or casters with locks are a practical feature for safe and flexible movement.

- Ensure Compliance with Standards: If your workshop requires cleanroom conditions, corrosion resistance, or explosion-proof features, verify that the crane meets the relevant standards. Aluminum gantries with smooth surfaces, protective coatings, or enclosed electrical systems can help maintain safe and compliant operations. Aluminum jib cranes are also a good option for localized lifting in controlled environments.

Conclusion

Selecting the right aluminum gantry crane is about more than just picking a model off a catalog. It requires a careful balance of load capacity, available workshop space, and the specific environmental conditions in which the crane will operate. Whether you are lifting small lab equipment, medium machinery parts, or heavier loads, matching the crane to your workshop's requirements ensures safe, efficient, and reliable operation.

Consulting with experienced suppliers or engineers can help confirm that your chosen crane meets operational, safety, and regulatory standards. This is especially important if your workshop demands cleanroom compatibility, corrosion resistance, or explosion-proof features.

From a compact 2 ton aluminum gantry for smaller tasks to a robust 3 ton aluminum gantry crane for heavier loads, the right choice enhances workflow, reduces maintenance, and maximizes productivity. Taking the time to plan, assess, and select carefully ensures your investment serves your workshop safely and effectively for years to come.